Carmel Forge had decades of expertise in hot forming of special steels, as well as nicked and tianium superalloys. We use closed-die forging, pressing and seamless ring-rolling to create sonic shapes for torque frames, disks, gears, rotating seals, bearing houses, cases, rings, rotors, flanges, hubs, impellers, and stab-shafts.

We are able to make disks, gears, impellers, hubs, stub-shafts and torque frames up to 450mmØ (Nickel Base) or 650 mmØ (Titanium Base) and a weight of 400Kg (880lb)

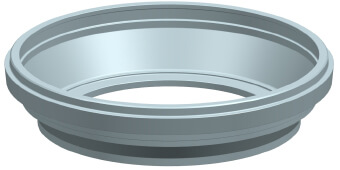

We can also make cases, seals, rings, flanges, rotating seals, (seamless rings) up to 1800 mm OD and a weight of 450 Kg (1000 lb.)